Web Menu

Product Search

Material Science of Comfort: 5D Armrest Pad Material Selection for Longevity and Softness

- 1 Core Material Choices: Analyzing the 5D Armrest Pad Material Selection

- 2 Balancing Act: Durability of PU Armrest Pads Against Tactile Comfort

- 3 Advanced Solutions: Gel vs PU Foam Armrest Pads in 5D Systems</HED

- 4 Procurement Criteria for Long-Term 5D Armrest Performance

- 5 Anji Xielong Furniture Co., Ltd.: Commitment to Armrest Innovation

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. What is the key performance difference between PU foam and Gel/TPE for a 5D Armrest pad?

- 6.2 2. How can I technically measure the softness of an armrest pad?

- 6.3 3. What is 'compression set' and why is it important for armrest pads?

- 6.4 4. When should I choose Gel vs PU foam armrest pads for a premium ergonomic chair?

- 6.5 5. What risk does poor 5D armrest pad material selection pose to the chair manufacturer?

In the ergonomic furniture industry, the 5D Armrest represents the pinnacle of adjustability. However, the mechanism is only as good as its contact point. For B2B buyers, the 5D Armrest pad material must strike a delicate balance between tactile softness, long-term durability, and structural integrity under constant friction. The ultimate success of the 5D Armrest depends on meticulous 5D armrest pad material selection and technical testing.

Core Material Choices: Analyzing the 5D Armrest Pad Material Selection

Manufacturers primarily utilize three families of materials for armrest pads, each presenting a different performance profile regarding cost, feel, and longevity.

Polyurethane (PU) Foam: Versatility and Density

- Advantages: PU is widely used due to its versatility, excellent molding capabilities, and low cost. It offers a spectrum of hardness levels (density) and good elastic properties, allowing for custom contouring.

- Disadvantages: Lower density PU is susceptible to compression set (permanent indentation) over time and may degrade when exposed to sweat and high UV light. This directly impacts the long-term Durability of PU armrest pads.

Thermoplastic Elastomers (TPE) and Gel Compounds: Enhanced Cushioning

- Advantages: TPEs and gel compounds offer superior pressure distribution and excellent heat-dissipating properties compared to standard foam. They provide a high degree of immediate comfort, significantly improving the perception when Evaluating soft armrest pad comfort.

- Disadvantages: These materials are generally heavier, more expensive, and may be less abrasion-resistant than high-density PU unless reinforced.

Armrest Pad Material Comparison Table

| Material Type | Tactile Comfort (Relative) | Compression Set Resistance | Abrasion Resistance |

|---|---|---|---|

| Low-Density PU Foam | High | Poor to Medium | Medium |

| High-Density PU Foam | Medium | Good | Good (Higher Durability of PU armrest pads) |

| Gel / TPE Compound | Excellent | Excellent | Medium |

Balancing Act: Durability of PU Armrest Pads Against Tactile Comfort

The core engineering challenge is achieving a pad that feels soft to the touch while possessing the structural fortitude to withstand years of abrasive use and sustained compression. This technical balance dictates both material density and surface finish.

Assessing Abrasion Resistance (Martindale Test)

- Testing Standard: While the Martindale test is primarily for fabrics, similar abrasion testing protocols are applied to PU pads. The surface finish must resist peeling, cracking, and thinning, which are common failure modes for materials with low Durability of PU armrest pads.

- Chemical Resistance: The pad must resist degradation from common contaminants like hand sanitizers, lotions, and cleaning solvents without losing its color or structural integrity.

The Role of Density and Rebound in Evaluating soft armrest pad comfort

Softness is a function of both initial hardness and rebound rate. A material may feel soft initially but compress permanently, leading to poor ergonomic support. High-rebound materials are crucial for Evaluating soft armrest pad comfort over an extended workday.

Hardness vs. Durability Comparison Table

| Pad Hardness (Shore A) | Tactile Feel | Expected Longevity |

|---|---|---|

| $\le 30$ | Very Soft, High Compression | Lower (Higher risk of permanent set) |

| $35 - 45$ | Optimal Balance | High (Best long-term balance for 5D Armrest pad) |

| $\ge 50$ | Firm, Less Comfort | Highest (High resistance to wear) |

Advanced Solutions: Gel vs PU Foam Armrest Pads in 5D Systems</HED

Heat Dissipation and Pressure Mapping

In the debate of Gel vs PU foam armrest pads, heat management is a key differentiator. Gel and TPE compounds generally have higher thermal conductivity than PU foam, effectively drawing heat away from the forearm. Pressure mapping tests confirm that gel materials distribute weight more evenly, reducing peak pressure points which cause fatigue and discomfort.

Technical Benchmarks: Technical specifications for armrest pad hardness (Shore A/C)

Procurement specifications should always include quantifiable metrics. Hardness is commonly measured using the Shore scale. Soft armrest pads are typically specified in the Shore A range, with target values between 35A and 45A to optimize comfort while ensuring mechanical stability. Specifying the exact Technical specifications for armrest pad hardness (Shore A) is necessary to maintain batch-to-batch consistency and high quality.

Procurement Criteria for Long-Term 5D Armrest Performance

For B2B buyers, specifying the 5D Armrest pad requires demanding data on compression set resistance (e.g., ISO 815), abrasion cycles, and the exact Shore hardness of the material. This technical documentation guarantees the product will deliver both the required comfort and the expected service life.

Anji Xielong Furniture Co., Ltd.: Commitment to Armrest Innovation

Anji Xielong Furniture Co., Ltd., established in 2019, is dedicated to the R&D, production, and sales of adjustable armrests, including advanced 5D Armrest systems. We recognize that superior user experience hinges on the quality of every component, especially the contact surface. Our technical team rigorously validates the 5D armrest pad material selection, performing extensive testing to ensure optimal Durability of PU armrest pads and other compounds. Adhering to our principle of "Quality first, customers first," we continuously innovate to pursue higher quality products, ensuring our partners receive armrests engineered for both ergonomic comfort and market-leading longevity.

Frequently Asked Questions (FAQ)

1. What is the key performance difference between PU foam and Gel/TPE for a 5D Armrest pad?

Gel/TPE offers superior pressure distribution and heat dissipation, enhancing long-term comfort, while high-density PU offers a better balance of cost and abrasion resistance, crucial for the Durability of PU armrest pads.

2. How can I technically measure the softness of an armrest pad?

Softness is measured using the Shore hardness scale (typically Shore A or C). For professional applications, pads should have Technical specifications for armrest pad hardness in the $35A-45A$ range for optimal comfort and durability.

3. What is 'compression set' and why is it important for armrest pads?

Compression set is the permanent deformation of the material after sustained load. Low resistance to compression set means the pad will develop a permanent indentation over time, severely compromising the comfort when Evaluating soft armrest pad comfort.

4. When should I choose Gel vs PU foam armrest pads for a premium ergonomic chair?

Choose gel or TPE when the priority is maximum pressure distribution, heat management, and plush tactile feel. Choose high-density PU when the priority is cost-efficiency and high abrasion resistance.

5. What risk does poor 5D armrest pad material selection pose to the chair manufacturer?

Poor material selection, particularly low durability material, leads to premature pad degradation (cracking, peeling), resulting in high warranty claims and damage to the brand's perception of quality.

Feel free to contact us

Feel free to contact us

- Product Fast Links

- Office Chair Armrest

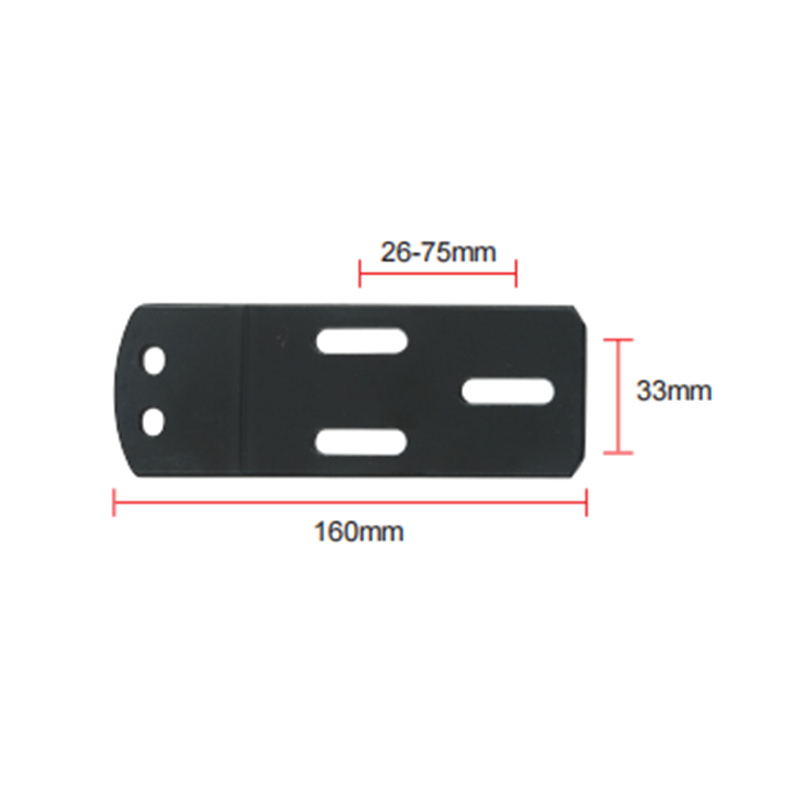

- Hardware Steel Plate

- Polyurethane PU Surface

- Casters

- Contact Information

- Tangpu Industrial Park, Anji County, Huzhou City, Zhejiang Province, China

- [email protected]

- +86-13567973388

English

English  Español

Español  عربى

عربى