Web Menu

Product Search

Achieving 5D Armrest Mounting Plate Standardization and Design Harmony

- 1 The Question of Universal Fit: Analyzing 5D Armrest Mounting Plate Standardization

- 2 Technical Compatibility: Using the Armrest Interface Compatibility Guide

- 3 Aesthetic and Functional Cohesion: Integrating 5D Armrest with Chair Design

- 4 Procurement Due Diligence for 5D Armrest Integration

- 5 Anji Xielong Furniture Co., Ltd.: Commitment to Armrest Innovation

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. Does the 5D Armrest use a truly universal mounting interface?

- 6.2 2. What is the biggest non-visual risk of poor integration?

- 6.3 3. Why is an Armrest interface compatibility guide essential for B2B procurement?

- 6.4 4. How does the concept of a Universal mounting hole pattern for armrests</strong > benefit manufacturers?

- 6.5 5. What is the key to successfully Integrating 5D armrest with chair design</strong > aesthetically?

For office chair manufacturers, integrating the advanced functionality of a 5D Armrest requires meticulous planning beyond simple procurement. Two critical technical hurdles must be cleared: verifying the 5D Armrest's physical mounting compatibility and ensuring its complex mechanical structure integrates seamlessly with the chair's aesthetic language and existing mechanism. This guide addresses the technical requirements for achieving reliable, high-volume production using advanced armrest systems.

The Question of Universal Fit: Analyzing 5D Armrest Mounting Plate Standardization

While true, universal fit does not strictly exist in the furniture industry, high-volume manufacturers converge on several common mounting plate patterns to streamline production and maximize component interchangeability. This practice allows suppliers to offer a measure of 5D armrest mounting plate standardization.

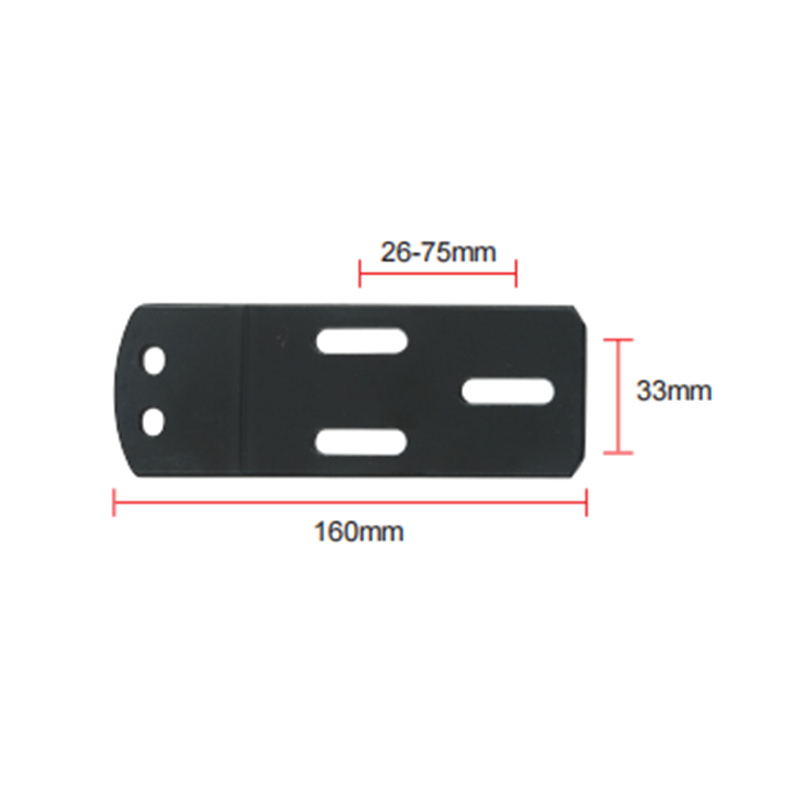

Commonality of Mounting Hole Patterns (BIFMA/ANSI Standards)

- Standardization Trend: Many adjustable armrests, including advanced 5D Armrest models, utilize bolt patterns conforming to general industry guidelines (often based on centers like 150mm x 200mm or similar metrics). Adherence to these common patterns simplifies the manufacturing process for the chair chassis.

- Technical Caveat: While the screw holes may align, the structural post clearance, height adjustment mechanism envelope, and the required chair mechanism geometry are often bespoke, creating a dependency on the armrest supplier's dimensional data.

Variability in Armrest Post Dimensions and Heights

The primary deviation lies in the post or upright section of the armrest mechanism. The required cut-out shape, material thickness, and vertical height of the post housing often vary significantly, impacting which armrests are compatible with a specific seat base mechanism.

Common Armrest Mounting Standards Table

| Compatibility Aspect | Standardization Level | Impact on Chair Assembly |

|---|---|---|

| Bolt Hole Center Distance | High (Supplier adherence to common BIFMA patterns) | Low-to-Medium (Relatively easy to match) |

| Post/Mechanism Housing Clearance | Low (Highly dependent on specific supplier design) | High (Requires custom tooling and design) |

| Interface Material Thickness | Medium | Medium (Affects structural integrity/fastener length) |

Technical Compatibility: Using the Armrest Interface Compatibility Guide

Effective B2B purchasing relies on a detailed Armrest interface compatibility guide provided by the component manufacturer, ensuring zero interference between the moving parts of the chair mechanism and the armrest base.

Factors Beyond Bolt Holes: The Role of Seat Mechanism Clearance

- Mechanism Interference: When the chair is reclined, the armrest base may clash with internal components (e.g., control levers, tilt mechanisms). This requires a detailed CAD check using the 5D Armrest supplier's 3D models.

- Structural Load Path: The attachment points must correctly transfer the load (e.g., up to 250 lbs per armrest under BIFMA testing) directly into the chair frame without causing stress concentration in plastic components.

Addressing Technical challenges of 5D armrest integration in Production

One of the chief Technical challenges of 5D armrest integration is managing the visual gap created by the complex mechanism. Achieving a small, consistent gap between the armrest body and the upholstered seat back requires extremely tight tolerance control from both the chair assembler and the armrest supplier.

Compatibility Risk Comparison Table

| Integration Risk Factor | Root Cause | Mitigation Strategy |

|---|---|---|

| Load-Bearing Failure | Mismatched mounting plate thickness or fastener strength. | Verify load path and fastener Technical specifications for 5D armrest. |

| Aesthetic Mismatch (Gap/Alignment) | Inconsistent armrest post casting or chair frame dimensions. | Strict adherence to GD&T (Geometric Dimensioning and Tolerancing). |

| Mechanism Collision | Lack of clearance between armrest base and tilt control box. | Mandatory 3D CAD simulation using the supplier's Armrest interface compatibility guide. |

Aesthetic and Functional Cohesion: Integrating 5D Armrest with Chair Design

Matching Design Language (Styling, Finishes, Material Flow)

Integrating 5D armrest with chair design is a visual and ergonomic requirement. The armrest is a high-touch component, and its styling—including the texture, finish (matte vs. gloss), and profile shape—must complement the chair's overall aesthetic. Successful integration often involves customizing the outer shroud or trim pieces to blend the armrest base into the chair frame.

The Importance of Universal mounting hole pattern for armrests in Mass Production

While the overall 5D Armrest mechanism is complex, suppliers prioritizing a Universal mounting hole pattern for armrests offer manufacturers significant agility. This allows for quick substitution between different armrest models (e.g., 3D to 5D) on the same chair frame, reducing tooling costs and accelerating product line diversification.

Procurement Due Diligence for 5D Armrest Integration

Manufacturers must demand more than just a mounting template. They need the full dimensional envelope, BIFMA load test reports, and the Armrest interface compatibility guide from the supplier to ensure the 5D Armrest seamlessly integrates without compromising the chair's overall structural certification.

Anji Xielong Furniture Co., Ltd.: Commitment to Armrest Innovation

Anji Xielong Furniture Co., Ltd. specializes in the R&D, production, and sales of adjustable armrests, including innovative 5D Armrest solutions. We deeply understand the Technical challenges of 5D armrest integration. Our engineering focus ensures that our components not only adhere to common mounting patterns, contributing to 5D armrest mounting plate standardization, but also come with the precise dimensional data required for seamless integration into diverse chair designs. Adhering to our purpose of "Quality first, customers first," we ensure our partners enjoy high-quality products and efficient services, fostering win-win cooperation in the furniture field.

Frequently Asked Questions (FAQ)

1. Does the 5D Armrest use a truly universal mounting interface?

No, a truly universal fit is rare due to the complexity of the mechanism. However, most high-quality suppliers adhere to common BIFMA-inspired bolt hole spacing, contributing to 5D armrest mounting plate standardization, which eases initial chair frame design.

2. What is the biggest non-visual risk of poor integration?

The biggest risk is structural failure. If the mounting interface does not correctly transfer load into the chair frame, the chair will fail BIFMA dynamic or static load tests, a primary concern when managing the Technical challenges of 5D armrest integration.

3. Why is an Armrest interface compatibility guide essential for B2B procurement?

The guide provides precise dimensional envelopes and clearance zones. It allows chair manufacturers to perform 3D CAD collision checks, preventing interference between the moving armrest base and the chair's internal tilt mechanism.

4. How does the concept of a Universal mounting hole pattern for armrests</strong > benefit manufacturers?

It allows manufacturers to use the same basic chair frame tooling to support multiple levels of armrest functionality (e.g., 3D, 4D, 5D), accelerating product diversification and reducing manufacturing complexity and costs.

5. What is the key to successfully Integrating 5D armrest with chair design</strong > aesthetically?

The key is matching the armrest's material finish, texture, and overall profile to the chair's primary structural components, often requiring the customization of the armrest's external shroud to create a visually cohesive unit.

Feel free to contact us

Feel free to contact us

- Product Fast Links

- Office Chair Armrest

- Hardware Steel Plate

- Polyurethane PU Surface

- Casters

- Contact Information

- Tangpu Industrial Park, Anji County, Huzhou City, Zhejiang Province, China

- [email protected]

- +86-13567973388

English

English  Español

Español  عربى

عربى