Web Menu

Product Search

How to improve the stability of railing installation with Three-Hole Steel Plate Handrail Column Base Embedded Plate?

- 1 Introduction

- 2 Stability challenges in railing installation

- 3 Design Concept of Three-Hole Steel Plate Handrail Column Base Embedded Plate

- 4 Installation advantages of Three-Hole Steel Plate Handrail Column Base Embedded Plate

- 4.1 4.1 The installation process is simple and saves construction time

- 4.2 4.2 Improve construction accuracy and reduce human errors

- 4.3 4.3 Reduce irregular construction and ensure long-term stability

- 4.4 4.4 Applicable to various construction environments and complex buildings

- 4.5 4.5 Save costs and improve cost performance

- 5 Safety improvement: How to ensure the long-term stability of the railing

- 5.1 5.1 Enhanced earthquake resistance: ensuring safety under extreme conditions such as earthquakes

- 5.2 5.2 Enhanced wind resistance: Resistant to strong winds and extreme weather conditions

- 5.3 5.3 Corrosion resistance: prolong the service life of the railing

- 5.4 5.4 Resistance to gravity and dynamic loads: Adaptation to high load areas

- 6 Environmental adaptability: performance under different building conditions

- 7 Conclusion: Why choose Three-Hole Steel Plate Handrail Column Base Embedded Plate to improve the stability of handrail installation

-

Introduction

In modern architecture and engineering design, railings are more than just a decorative element. They play a vital role in ensuring the safety and structural stability of buildings. From residential and commercial buildings to high-rise buildings and bridges, the stability of the railing system is directly related to people's life safety. Especially in high-risk areas such as balconies, stairs, corridors, etc., the function of railings is not only to separate spaces or provide aesthetic appearance, but also a safety barrier to prevent falls. Therefore, the stability of railings is undoubtedly the most important part of building safety design.

Although traditional railing installation methods are widely used, they often have certain limitations. In particular, when dealing with environmental pressure and wear and tear during long-term use, the railings may gradually loosen, resulting in structural instability and even safety hazards. In some high-rise buildings or special working conditions, traditional installation methods are difficult to provide sufficient support and stability, which may pose a considerable threat to the safety of the building.

In order to improve the installation stability of the railings, engineering designers began to explore more innovative and efficient solutions. Among the many technologies, the Three-Hole Steel Plate Handrail Column Base Embedded Plate technology has quickly attracted attention in the industry due to its excellent stability, load-bearing capacity and convenient installation method. This technology significantly improves the overall stability of the railing system by making the connection between the railing and the building structure tighter and firmer, especially under high loads and extreme conditions, ensuring that the railings always remain stable and avoid potential safety hazards.

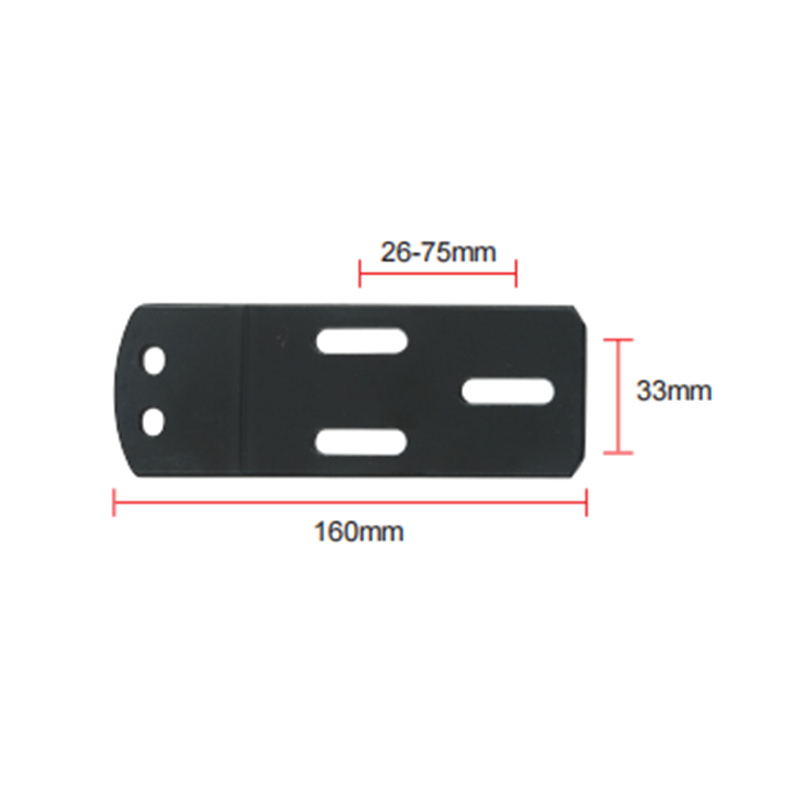

248.4g Three-Hole Steel Plate Handrail Column Base Embedded Plate A-02

-

Stability challenges in railing installation

In construction projects, railing installation is an important part that cannot be ignored. It not only involves aesthetics and functionality, but is also directly related to the safety and service life of the building. Although modern building design is becoming more and more advanced, the installation stability of railings still faces many challenges. Whether it is residential, commercial buildings, or special structures such as public facilities, high-rise buildings and bridges, the installation of railings faces a series of stability issues, which affect their performance in long-term use.

2.1 Stability issues of traditional installation methods

Most traditional railing installation methods rely on simple bolting or welding techniques. Although these methods are convenient and low-cost, they have several significant drawbacks, especially when faced with long-term use, extreme climates and external forces:

Uneven distribution of local loads: Traditional installation methods usually rely on a single or a few fixing points. This method is prone to stress concentration, causing the base of the railing to gradually loosen. As the use time increases, the loose parts may cause the railing to be unstable or even fall off completely.

Limited ability to withstand external forces: Especially in high-rise buildings or outdoor environments, railings must not only withstand vertical loads, but also external forces such as wind, earthquakes, or human impact. Traditional installation methods often fail to provide sufficient support and are prone to safety hazards when dealing with strong winds, large-scale impacts, or vibrations.

Environmental factors: Traditional railing fixing methods may not be able to adapt to extreme climates or humid environments. For example, in coastal areas or areas with frequent rainfall, corrosive environments may aggravate the loosening of bolts or corrosion of metal parts, resulting in reduced stability of the railing.

Irregular construction: Traditional installation methods rely on manual fixation, which may result in irregular installation due to differences in worker operations. Even in the same project, the installation quality of different workers may vary, making it difficult to ensure the stability of the overall railing system.

2.2 Stability issues under high load and extreme conditions

The stability of railing installation in high-load areas and extreme conditions is particularly important, especially in some special buildings and facilities. The following situations are particularly prominent:

Stress issues in high-rise buildings: In high-rise buildings, railings need to bear large lateral forces due to wind pressure, vibration, etc. Traditional installation methods may not be able to withstand these continuous external forces, resulting in the risk of unstable railing foundations.

Special needs of bridges and public facilities: Railings in bridges, public places, and elevated buildings usually need to withstand greater dynamic loads, such as vibration and impact generated by cars or pedestrians passing by. These dynamic loads require higher stability for the railings, which traditional fixing methods often have difficulty coping with.

Weather changes and temperature differences: Extreme temperatures, alternating hot and cold climate conditions, and extreme weather such as storms may also affect the stability of the railing. Traditional fixing methods lack adaptability to such environmental changes and are prone to loosening or deformation of the installation part due to material expansion or contraction.

2.3 Security risks and maintenance problems

Instability of railings not only poses a potential safety hazard, but can also result in high repair and replacement costs. Especially in public buildings and high-rise buildings, loose or unstable railings often require frequent inspections and maintenance:

Unstable railings bring safety hazards: In high-rise buildings and stairwells, unstable railings will greatly increase the risk of falling. Especially for special groups such as the elderly and children, the safety of railings is directly related to personal safety. Once the railings are loose or fall off, serious injuries may occur.

Frequent maintenance and replacement: Under traditional installation methods, due to the instability of railings, building managers usually need to perform frequent maintenance work. The maintenance of railings in high-rise buildings requires investment in manpower and equipment, which undoubtedly increases the operation and maintenance costs and also affects the normal use of the building.

Prolonged maintenance shutdowns: When railings become loose or damaged in some public buildings, it may be necessary to close some areas for repairs, which will affect the daily operation of the building and may even cause inconvenience or danger to people inside the building.

2.4 Increased construction time and cost

Due to the many uncertainties in the traditional railing installation method, multiple adjustments and corrections are often required during the construction process, which leads to a longer construction period and increased costs:

Repeated adjustments and corrections: During the installation of the railings, due to the limitations of traditional methods, the construction team often needs to make multiple adjustments during the installation process to ensure the stability of the railings. This repeated adjustment not only wastes time, but also increases labor costs.

Poor quality control: Due to the lack of uniform installation standards and techniques, inconsistent quality often occurs during the construction process, resulting in railings being loosely installed in some areas, which requires re-correction. This further increases the construction time and cost of the project.

-

Design Concept of Three-Hole Steel Plate Handrail Column Base Embedded Plate

In the field of technical innovation in building safety and railing installation, the Three-Hole Steel Plate Handrail Column Base Embedded Plate is a new solution that is gradually replacing traditional railing installation methods with its unique design concept, especially showing significant advantages in improving stability and load-bearing capacity. Its core design concept focuses on multiple factors such as structural optimization, load distribution, durability, and construction convenience, aiming to meet the challenges of traditional installation methods and provide a more stable and long-term railing fixing solution.

3.1 Stability advantages of three-hole steel plate design

Traditional railing installation usually relies on simple single-point fixing or uses relatively simple plates and bolts to connect, while the Three-Hole Steel Plate design optimizes the distribution of loads. By designing three fixing holes on the base steel plate, this design method can significantly improve the stability of the railing installation, which is specifically reflected in the following aspects:

Evenly distributed load: The three-hole design effectively disperses the stress transmitted from the railing to the foundation by increasing the number of fixing points. Each fixing point shares part of the load, avoiding local stress concentration and reducing damage or loosening caused by excessive stress.

Enhanced shear and tensile resistance: The three fixing points provide more connection surfaces, which enhance the shear and tensile resistance of the connection parts, can better resist the effects of external forces, and ensure the stability of the railing under various extreme conditions.

Higher earthquake and wind resistance: In high-rise buildings or earthquake-prone areas, railings need to withstand strong vibrations or wind. The three-hole steel plate design makes the load distribution more even, which can effectively reduce the vibration transmission of the building and improve the railing system's ability to withstand vibrations or wind pressure.

3.2 Embedded design improves overall stability

The embedded design of the Three-Hole Steel Plate Handrail Column Base Embedded Plate is one of its core innovations. Unlike the traditional surface installation method, this embedded design embeds the steel plate into the building structure to form a more stable connection method:

Close integration with the building structure: The embedded design can deeply integrate the base of the railing with the building structure itself, avoiding the loosening problem that may occur in traditional surface installation methods. Through this design, the contact area between the railing column and the foundation is greatly increased, effectively improving the fixing force of the railing.

Reduce stress transmission path: Since the base plate is embedded in the building structure, the stress transmission path of the railing is effectively optimized when it is stressed, reducing the instability caused by mechanical effects. The embedded connection method helps to transmit external forces directly to the main body of the building, thereby reducing the direct impact on the railing column.

Enhanced durability: Compared with traditional fixing methods, the embedded structure has significantly improved firmness and durability, and can cope with problems such as friction and corrosion caused by long-term use, thereby extending the service life of the railing.

3.3 Three-hole design improves construction flexibility and convenience

The design of the three-hole steel plate railing column base embedded plate not only excels in stability and safety, but also provides great flexibility and convenience during the construction process. The following are the main construction advantages brought by this design:

Simplify the construction process: Compared with the traditional multiple adjustments and corrections, the design of the three-hole steel plate makes the installation process more standardized and systematic. Construction workers only need to install according to the specified fixed points, which greatly reduces human errors and adjustment time during construction and shortens the construction period.

Embedded foundation design: The three-hole design allows the foundation to be embedded in the early construction stage, so that the railing columns can be quickly installed during the later construction process, reducing the process of multiple links and improving project efficiency.

Efficient accessory combination: Since the structure of the three-hole steel plate is relatively simple, fewer accessories are required during construction, which not only reduces the complexity of material procurement, but also reduces construction costs. In addition, the simplified design also makes installation easier to carry out standardized operations, reducing the requirements for the technical level of construction personnel.

3.4 Improve the adaptability and versatility of the railing system

The design of the three-hole steel plate railing column base embedded plate is also highly adaptable and can meet the needs of various buildings and environmental conditions. Whether it is a residential, commercial building, bridge or high-rise building, this design can be flexibly applied to ensure the stability and safety of the railing.

Suitable for different building types: Whether it is a high-rise building or a low-rise residence, the three-hole steel plate railing base embedded plate can provide strong support. For special buildings (such as bridges, public facilities, etc.), this design provides additional stability, especially under extreme conditions such as strong winds and large vibrations, it can maintain the stability of the railing.

Meeting the needs of special working conditions: The three-hole steel plate design is particularly important for some high-load areas (such as stairs, balconies, corridors, etc.). It can adapt to the needs of large-scale dynamic loads, such as pedestrians passing, transportation equipment passing, etc., and improve the safety of the railing system.

Flexible Adjustment and Replacement: The design not only provides stability, but also has a certain degree of adjustability and easy replacement functions, ensuring that when the railing is damaged or needs to be rearranged, it can be quickly adjusted and replaced without affecting the stability of the overall structure.

3.5 Material selection and durability

In order to ensure the long-term service life and durability of Three-Hole Steel Plate Handrail Column Base Embedded Plate, the design usually uses high-strength steel, corrosion-resistant materials or galvanized coatings. These materials can effectively resist corrosion, oxidation and wear in the external environment:

High-strength steel: The use of high-strength steel ensures the compression and tensile strength of the railing foundation, which can withstand the stress under high load conditions and maintain long-term stability.

Anti-corrosion coating: For outdoor environments or high humidity areas, anti-corrosion coating can effectively extend the service life of the railing system and avoid rust and corrosion problems of metal parts.

-

Installation advantages of Three-Hole Steel Plate Handrail Column Base Embedded Plate

As an innovative railing fixing solution, the Three-Hole Steel Plate Handrail Column Base Embedded Plate not only solves the stability problem of traditional installation methods in design, but also has multiple advantages in the installation process itself. Compared with traditional installation methods, the use of this embedded base design can greatly improve installation efficiency, reduce error rates, improve construction quality, and reduce costs. The following will analyze the advantages of this installation method in detail.

4.1 The installation process is simple and saves construction time

Traditional railing installation often requires multiple adjustments and complex prefabrication work, resulting in a long construction period, especially in complex building structures. The installation of the Three-Hole Steel Plate Handrail Column Base Embedded Plate adopts a simplified construction solution, and its design itself is easy to install quickly:

Reduce installation steps: Since the three-hole steel plate design is easy to connect and fix directly with the railing column, the installation process is greatly simplified. The installer only needs to fix the steel plate to the pre-set foundation, and then connect the railing column with the base steel plate by bolts, which reduces many cumbersome steps in traditional installation methods.

Reduce adjustment time: The three-hole design provides fixed installation points. Installers no longer need to adjust the positions of multiple fixed points, but only need to operate according to the standard position. This fixing mode significantly reduces the adjustment time caused by inaccurate docking, which effectively improves the construction progress.

Integrated construction: Due to the embedded design of the three-hole steel plate, the railing foundation can be combined with the structure of the main building, completing multiple tasks at one time, thereby reducing other installation processes involved in the construction process. The overall construction period is greatly shortened compared to traditional methods.

4.2 Improve construction accuracy and reduce human errors

Traditional railing installation often relies on manual operation, and due to the complex construction environment, errors or non-standard installation are prone to occur, resulting in unstable railing fixation and even safety hazards. The design of the Three-Hole Steel Plate Handrail Column Base Embedded Plate significantly improves construction accuracy and reduces human errors through its standardized and modular installation method:

Standardized design: The three-hole steel plate provides clear installation positions and fixing holes. Construction workers can install it according to the predetermined standard steps to ensure that each railing is firm and meets the requirements. This standardized design reduces the problem of inconsistent construction quality caused by differences in worker experience.

Accurate fixing holes: The three fixing holes are precisely designed and calculated to ensure the close connection between the railing column and the base plate, reducing installation problems caused by hole position errors. Any small error will affect the stability of the railing, and the three-hole design ensures maximum stability through precise hole spacing and docking methods.

Efficient quality control: During the construction process, since each three-hole steel plate installation step can be subject to standardized inspection, construction personnel and supervisors can more conveniently monitor quality, reducing quality defects and subsequent maintenance costs.

4.3 Reduce irregular construction and ensure long-term stability

The long-term stability of the railing installation is directly related to the safety of the building. Traditional installation methods may have stability problems due to non-standard construction or inadequate maintenance. The installation method designed by Three-Hole Steel Plate Handrail Column Base Embedded Plate can ensure the long-term stability of the railing in several ways:

Solid foundation: Since the steel plate embedded design directly combines the railing foundation with the building body, the fixation is significantly better than the traditional surface installation method. This design reduces the loosening phenomenon that may occur during installation, especially when the building is subjected to long-term vibration, temperature changes and external pressure.

Earthquake and wind resistance: In high-rise buildings or special structures, railings will face greater external forces, such as strong winds, earthquakes, etc. The design of the three-hole steel plate provides uniform force distribution during installation, enhances the earthquake and wind resistance of the railing, and ensures its long-term stability.

Anti-corrosion treatment: Three-hole steel plates are usually treated with anti-corrosion treatment (such as galvanizing, spraying, etc.) during the manufacturing process. These treatments can effectively resist corrosion factors such as moisture and salt in the external environment, and further improve the long-term stability of the railing foundation.

4.4 Applicable to various construction environments and complex buildings

Traditional railing installation methods are often limited by factors such as construction environment and building structure. In some special buildings or complex construction environments, traditional installation methods may be difficult to meet the requirements, while the Three-Hole Steel Plate Handrail Column Base Embedded Plate provides higher adaptability and can flexibly respond to construction needs in different environments:

Suitable for complex structures: In irregular and complex shaped building structures, the embedded design of the three-hole steel plate railing foundation can adapt to different fixed point layouts. The construction personnel only need to adjust the position of the foundation plate according to the specific conditions of the structure to ensure the stability and reliability of the railing.

Adapt to extreme weather conditions: The embedded design of the three-hole steel plate makes it more resistant to changes in the external environment. In extreme weather conditions such as high temperature, low temperature, and heavy humidity, the steel plate and railing system can maintain stable performance and avoid loosening or damage of the railing due to environmental changes.

High load and special usage requirements: For high-load areas, the three-hole steel plate provides a stronger fixing force, which can effectively cope with special requirements such as pedestrian passage and large equipment passage, ensuring the safety and stability of the railing system.

4.5 Save costs and improve cost performance

Traditional railing installation often leads to high overall costs due to cumbersome procedures and high labor costs. The installation method of Three-Hole Steel Plate Handrail Column Base Embedded Plate has significant cost advantages:

Reduce labor costs: Since the installation method of the three-hole steel plate railing foundation is relatively simple, the skill requirements required for construction workers are relatively low, reducing the need for highly skilled workers and reducing labor costs. In addition, due to the short installation time, the overall construction cost is effectively controlled.

Reduced maintenance and replacement costs: Since this design improves the stability of the railing, it reduces the maintenance and replacement costs caused by looseness, deformation and other problems. In the long run, the maintenance cost of the railing system using three-hole steel plates is lower than that of traditional installation methods.

High cost performance: Although the initial investment of three-hole steel plates may be slightly higher than traditional installation methods, due to their fast installation speed, high stability and low maintenance costs, the overall cost performance is extremely high and it is a solution worth investing in.

-

Safety improvement: How to ensure the long-term stability of the railing

As an important safety facility in a building, the stability of the railing is directly related to the safety of the users. In various environments, the long-term stability of the railing faces a series of challenges, such as the action of external forces, the movement of the building itself, and the influence of environmental factors. Therefore, ensuring the long-term stability of the railing is an important part of ensuring the safety of the building.

5.1 Enhanced earthquake resistance: ensuring safety under extreme conditions such as earthquakes

In high vibration areas, especially those with frequent earthquakes, railings need to withstand greater vibration forces. Traditional railing installation methods often fail to take into account the impact of vibration, causing the railings to loosen or even fall off during an earthquake, thus posing a safety hazard. The Three-Hole Steel Plate Handrail Column Base Embedded Plate significantly improves the seismic resistance of the railing through the following designs:

Uniform force distribution: The three-hole steel plate design provides stable support points through three fixed holes, making the force of the railing column more uniform. When an earthquake or other vibration event occurs, the vibration force can be evenly distributed through these fixed points, thereby reducing the phenomenon of excessive local force and avoiding the loosening or falling problems common in traditional installation methods.

Improved bending resistance: The three-hole steel plate effectively improves the bending resistance of the railing post by providing an additional support point, avoiding the risk of bending or breaking under strong vibrations. Through this design, the railing can maintain its stability during multiple vibrations, ensuring the safety of residents or users.

Strengthen the overall structure: The three-hole steel plate foundation embedded design can be more closely integrated with the main body of the building, improving the stability of the overall structure. The close integration between the railing column and the foundation makes the entire system more seismic-resistant under earthquakes or strong vibrations, thereby effectively reducing the damage caused by earthquakes.

5.2 Enhanced wind resistance: Resistant to strong winds and extreme weather conditions

In high-rise buildings, seaside areas, or other places exposed to extreme weather conditions, the impact of strong winds on railings cannot be ignored. Traditional railing installation methods may not be able to withstand the pressure caused by extreme wind speeds, causing the railing to lose stability. The design of the Three-Hole Steel Plate Handrail Column Base Embedded Plate provides stronger wind resistance:

Strong fixation: The three-hole steel plate design provides a more solid fixing point, so that the railing can be stably maintained in place when subjected to strong winds, and will not be displaced or fall off due to excessive wind force. This solid foundation avoids the phenomenon of wind blowing down the railing that may occur in traditional installations.

Uniform distribution of wind resistance: The wind force on the railing will be evenly distributed through the three-hole steel plate. This design effectively avoids the wind force from concentrating on a specific location and prevents loosening or damage caused by uneven force. Especially in extreme weather conditions such as storms and typhoons, the railing can better withstand the impact of strong winds.

Adapt to changing climate: Three-Hole Steel Plate Handrail Column Base Embedded Plate can not only withstand strong winds, but also adapt to other extreme climate conditions. Under these conditions, the high and low temperature resistance of the steel plate ensures the stability of the railing foundation, and will not cause expansion, contraction or corrosion due to temperature changes.

5.3 Corrosion resistance: prolong the service life of the railing

In a humid, high-salinity, or heavily polluted environment, the handrail base is susceptible to corrosion. The handrail base made of traditional materials may become less stable, even break or deform due to corrosion, thus affecting safety. However, the Three-Hole Steel Plate Handrail Column Base Embedded Plate effectively extends the service life of the handrail in the following ways:

Anti-corrosion treatment: Three-hole steel plates are usually treated with anti-corrosion treatments, such as hot-dip galvanizing, spraying anti-corrosion coatings, etc. These anti-corrosion treatments can effectively protect the steel plates from corrosion by moisture, acid rain, salt water and other corrosive substances, delay the aging process of the steel plates, and thus improve the long-term stability of the railing system.

High durability: Steel itself has high durability and can maintain its stability for a long time in harsh environments. In corrosive environments, the combination of steel and anti-corrosion coating can ensure that the steel plate is not affected by external environmental factors and ensure the strength and stability of the railing foundation.

Reduced maintenance requirements: Due to the anti-corrosion properties of the three-hole steel plate, the maintenance requirements of the railing foundation are greatly reduced, avoiding frequent repairs and replacements, and saving maintenance costs in long-term use.

5.4 Resistance to gravity and dynamic loads: Adaptation to high load areas

In some high-load areas, such as stairs, balconies or handrails, the foundation of the railing needs to withstand large static and dynamic loads. Traditional installation methods may cause the railing to loosen or become damaged after being under pressure for a long time. The Three-Hole Steel Plate Handrail Column Base Embedded Plate provides a more effective solution in this regard:

Increased load-bearing area: The three-hole steel plate design can greatly increase the contact area between the railing column and the foundation, so that the railing can more evenly distribute the pressure and impact force from pedestrians. Even in high-load areas, the stability of the railing will not be affected.

Withstand impact and dynamic loads: During use, the railing may encounter collisions with pedestrians or equipment, and these dynamic loads may have a certain impact on the stability of the railing. The three-hole steel plate design can effectively disperse these external forces, ensuring that the railing can withstand greater impacts and loads without loosening, deformation or falling off.

Adapt to different load requirements: Different building environments have different load requirements for railings. The three-hole steel plate foundation design can adjust the load distribution according to actual needs by providing a variety of hole settings, so that the railing system can adapt to different environments and load conditions.

-

Environmental adaptability: performance under different building conditions

In modern buildings, different geographical environments, climate conditions and building structure requirements pose different challenges to the stability and durability of railings. The design of the Three-Hole Steel Plate Handrail Column Base Embedded Plate is to adapt to various complex environmental conditions and ensure that the railing system can perform at its maximum efficiency in a variety of building scenarios. Whether it is at the seaside, in high-temperature areas, or in high humidity, cold, or vibration-prone environments, the three-hole steel plate foundation can provide excellent performance and ensure the long-term stability and safety of the railing.

6.1 Coastal areas: coping with high salinity and humid environments

Buildings in coastal areas face harsh environmental conditions, especially high-salinity sea breeze, humidity and seawater erosion. In this environment, the railing foundation needs to have strong corrosion resistance to ensure long-term stability and safety.

Anti-corrosion performance in high-salinity environments: The high-salinity air and seawater in coastal areas are extremely corrosive. Traditional railing foundations are prone to corrosion, rust and structural fatigue under long-term salt spray erosion, causing the railings to loosen or even break. The anti-corrosion treatment technology (such as hot-dip galvanizing, anti-corrosion coating, etc.) used in the three-hole steel plate foundation can effectively resist the salt spray corrosion brought by the sea breeze, greatly improve the corrosion resistance of the railing foundation, and enable it to maintain stable performance for a long time in coastal areas.

Moisture resistance and rust resistance: After anti-corrosion treatment, the steel plate material itself can effectively resist the erosion of the railings by water vapor and salt spray in a humid environment. It is not easy to rust, thus avoiding the threat of a humid environment to the stability of the railing structure.

Extended service life: As the Three-Hole Steel Plate Handrail Column Base Embedded Plate has extremely high corrosion resistance, the railing system can maintain a long service life even in a seaside environment, avoiding the need for frequent replacement and repair, and reducing maintenance costs.

6.2 High-temperature areas: Coping with hot weather and temperature changes

In high temperature areas or environments with large temperature differences, the expansion and contraction of materials is an issue that cannot be ignored. Conventional railing base materials may expand, deform, or age when exposed to extreme temperatures, thus affecting the stability of the railing.

High temperature resistance: The high-strength steel plate material used in the Three-Hole Steel Plate Handrail Column Base Embedded Plate has good high temperature resistance and can withstand thermal stress in high temperature environments without deformation. Under high temperature conditions, this steel plate material will not expand excessively, and can maintain the stability of the railing foundation, ensuring the durability of the railing system in hot environments.

Adapt to temperature differences: In areas with large temperature differences, the temperature difference between day and night and seasonal changes may cause the building structure to expand or contract. The design of the three-hole steel plate foundation takes this into consideration. Its structural firmness and anti-loosening function can effectively cope with the pressure changes caused by such temperature differences and maintain the stability of the railing system.

Improve material durability: In high temperature environments, the durability of steel is particularly important. The three-hole steel plate can maintain the strength and toughness of the material itself through the treatment of high temperature resistant coating or alloy material, and can still maintain the structural integrity and strength of the railing even under long-term high temperature exposure.

6.3 Cold Regions: Resistance to Low Temperature and Frost Heave

The construction environment in cold regions is often accompanied by extreme weather conditions such as low temperature, ice and snow. In low temperature environments, conventional materials may experience problems such as frost heave and embrittlement, resulting in reduced stability of the railings and even the risk of breakage.

Anti-frost heave ability: The steel plate material used in the Three-Hole Steel Plate Handrail Column Base Embedded Plate has good anti-frost heave performance and can adapt to temperature changes in low temperature environments. Even in an environment below zero degrees, the steel plate will not expand or shrink, avoiding loosening or damage caused by frost heave.

Retaining toughness: In extremely cold environments, some materials become brittle and easily break or damage. The design of the three-hole steel plate uses high-toughness steel to ensure that it can still maintain sufficient tensile strength and ductility at low temperatures, avoiding brittleness of the material due to low temperatures.

Anti-freeze protection: The surface of the steel is usually specially treated to be resistant to low temperatures to prevent frost and ice accumulation on the surface of the steel plate due to low temperatures, which would further affect the stability of the railing.

6.4 Earthquake-prone areas: seismic performance and structural stability

In earthquake-prone areas, buildings need to withstand strong vibrations, and the stability of railings is particularly important. Traditional railing installation methods often ignore this point, which can easily cause damage or collapse during an earthquake. The Three-Hole Steel Plate Handrail Column Base Embedded Plate design can effectively improve the seismic performance of railings:

Multi-point fixing design: The three-hole steel plate design provides multiple fixing points, which enables the railing to evenly distribute seismic forces, reduce pressure concentration at a single point, and prevent the railing from loosening or falling off during vibration.

Enhanced seismic toughness: The toughness and bending resistance of the steel plate enable it to better withstand the impact of seismic waves. Especially when an earthquake occurs, the railing foundation can maintain its stability in large vibrations through the structural performance of its steel plate to ensure the safety of users.

Stable structure: In extreme cases such as earthquakes, the combination of three-hole steel plates and building foundations allows the railing columns to form a stronger connection with the main building, improving the overall earthquake resistance and reducing the impact of earthquakes on the railings.

-

Conclusion: Why choose Three-Hole Steel Plate Handrail Column Base Embedded Plate to improve the stability of handrail installation

In modern construction projects, railings are not only an important part of safety protection, but also a reflection of overall design and functionality. The stability of railings directly affects the safety of users and the reliability of building structures. Choosing a suitable railing installation foundation is crucial to ensure the long-term stability of the railing. As an innovative railing installation foundation system, the Three-Hole Steel Plate Handrail Column Base Embedded Plate has shown great potential in improving railing stability with its unique design advantages.

The Three-Hole Steel Plate Handrail Column Base Embedded Plate provides a more solid and durable installation method. Through its high-strength steel plate material and three-hole fixing design, it can effectively improve the connection strength between the railing column and the foundation. This enhanced connection method ensures that the railing can withstand various pressures in the external environment and during use, including vibration, impact, temperature changes, etc.

Compared with traditional installation methods, the three-hole steel plate foundation can significantly reduce the loosening or tilting of the railing caused by external forces (such as wind pressure, collision, etc.). Through its precise design, the three-hole steel plate foundation ensures the accuracy and firmness of the railing installation, thereby effectively improving the long-term stability of the railing system and reducing the need for subsequent maintenance and repair.

As the construction industry's requirements for safety, stability and construction efficiency continue to increase, the Three-Hole Steel Plate Handrail Column Base Embedded Plate has become the preferred solution for railing installation in modern buildings due to its excellent performance and unique design concept. It can not only effectively improve the stability and safety of the railing system, but also achieve more efficient and economical operations in construction.

In future construction projects, with the emphasis on environmental protection and sustainable development, the three-hole steel plate foundation will be widely used in more fields and building types due to its excellent durability and adaptability. With the continuous advancement of technology, the Three-Hole Steel Plate Handrail Column Base Embedded Plate is expected to further optimize the design, improve installation efficiency, and provide a safer, more stable and economical solution for the construction industry.

Therefore, choosing Three-Hole Steel Plate Handrail Column Base Embedded Plate is not only an investment in the stability of the railing installation, but also an important guarantee for the future safety, efficiency and sustainability of the building.

Feel free to contact us

Feel free to contact us

- Product Fast Links

- Office Chair Armrest

- Hardware Steel Plate

- Polyurethane PU Surface

- Casters

- Contact Information

- Tangpu Industrial Park, Anji County, Huzhou City, Zhejiang Province, China

- [email protected]

- +86-13567973388

English

English  Español

Español  عربى

عربى