Product category

Contact Us

Ergonomic Office Gaming Chairs Armrests Manufacturers

-

XL-309-5D

309 Strong Nylon PU Adjustable Folding 5D Armrests, Can Rotate Inside and Outside

-

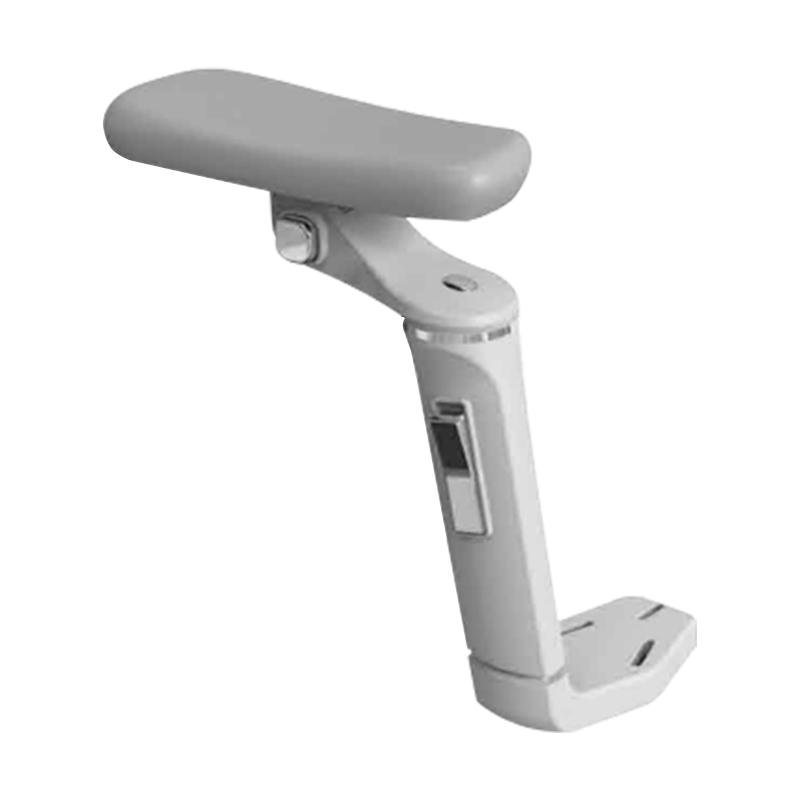

XL-309A-5D

309A Gray 5D Armrest Suitable for Plastic Computer Chair Adjustable Chair, Multi-Function Rotation Lifting

-

XL-709A-5D

709A Mesh Office Chair Adjustable High Back Ergonomic Chair 5D Armrests, Super Multi-Function Lift and Rotate

-

XL-709-5D

709 Swivel PU Leather 5D Armrest for Nylon Base High Back Office Chair

-

XL-709A-5D(lift and stretch)

709A-5D (Lift and Stretch) Office Furniture Chrome-Plated Multifunctional Armchair Parts-5D

-

XL-309-5D (lift and stretch)

309-5D (Lift and Stretch) Office Furniture Hardware Chrome-Plated Adjustable Armrest Parts-5D

-

XL-709A-5D (button version)

709A-5D (Button Version) Office Chair Furniture Chair Chrome 5D Multifunctional Armrest Chair Parts

-

XL-309-5D (button version)

309-5D (Button Version) 5D Hardware Chrome-Plated Black Adjustable Armrest Parts

-

XL-711-5D

711-5D Gaming Chair Chrome Aluminum Alloy Multifunctional Armchair Parts-5D

-

XL-711A-5D

711-5D Grey Chrome Aluminum Gaming Chair Office Chair 5D Armrest

-

XL-307-4D

307 Office Chair Parts Plastic Nylon PU Folding 4D Armrest, Multi-Angle Adjustable Seat Armrest

-

XL-306A-4D

306A Fully Adjustable Nylon 4D Armrests, The Armrests Can Be Adjusted to Fit the Arms

About Us

Our company is also constantly innovating and expanding, pursuing higher quality products. We welcome sincere cooperation with colleagues in the furniture field to create a win-win situation together.

News

Industry Knowledge Extension

How to ensure that the multi-dimensional (1D/2D/3D/4D/5D) adjustment function of the ergonomic adjustable nylon office gaming chair armrest is stable and reliable?

1. Clarify the technical standards and core requirements of the multi-dimensional adjustment function

The 1D to 5D adjustment function of the ergonomic office gaming chair armrest is essentially to meet the user's dynamic adjustment needs for the armrest height, front and back, left and right, angle, rotation and other directions through the mechanical structure design of different dimensions. Among them:

1D adjustment usually refers to a single height adjustment, and it is necessary to ensure that the jam rate during vertical lifting is less than 0.5%;

2D adjustment adds the front and back sliding function, requiring the parallelism error of the sliding guide rail to be ≤0.3mm;

3D adjustment adds left and right swing or angle rotation, and the coaxiality of the swing axis must be guaranteed to be ≤0.15mm;

4D adjustment is mostly a three-dimensional angle + height compound adjustment, and the structural gap must be controlled within 0.5-1mm;

5D adjustment belongs to full-dimensional adjustment, and it is necessary to take into account the independence of each axis movement and linkage stability.

Taking the technical standards of Anji Xielong Furniture Co., Ltd. as an example, the armrest adjustment system developed by it needs to pass 100,000 cycles of testing without failure, which requires a complete reliability guarantee system from material selection to structural design.

2. Material selection: Building a foundation for durability

The performance of nylon material directly affects the stability of the adjustment mechanism and needs to be controlled from the following dimensions:

Base material selection: PA66+30% glass fiber reinforced nylon is used, with a tensile strength of ≥80MPa and a bending modulus of ≥2500MPa, which can withstand vertical pressure of more than 50kg without deformation. Environmentally friendly nylon raw materials are selected, and the formaldehyde emission is ≤0.05mg/m³ tested by SGS, and it has passed the UL94 V-2 flame retardant certification, which improves the rigidity of the material while ensuring safety.

Additive addition: Add silicone lubricant to improve the friction coefficient of nylon, so that the static friction coefficient of the adjustment process is ≤0.3, and the dynamic friction coefficient is ≤0.25, to avoid adjustment jams; add antioxidants (such as hindered phenols) to extend the aging life of the material in daily use to more than 5 years.

Structural optimization: Use metal inserts (such as copper alloy or stainless steel) in key parts such as adjustment sleeves and gears, and use injection molding embedding technology to enhance the bonding force between nylon and metal, with a pull-out strength of ≥30MPa to prevent plastic fatigue fracture caused by long-term adjustment.

3. Mechanical structure design: precision and anti-loosening technology

The core of the stability of multi-dimensional adjustment lies in the anti-fatigue design of the mechanical structure:

Height adjustment mechanism: adopts gear rack + pawl locking structure, rack module ≥0.5, tooth angle 20°, pawl and rack meshing depth ≥2mm, and cooperates with spring tension (2-3N) to ensure no looseness after locking. The technical team of Anji Xielong Furniture Co., Ltd. optimized the stress distribution of the gears through finite element analysis, so that the maximum stress at the root of the tooth is ≤60% of the yield strength of the material.

Front-to-rear/left-to-right sliding mechanism: using double-track guide + ball bearing design, the guide straightness is ≤0.1mm/m, the ball diameter tolerance is ±0.01mm, and the limit stopper (stroke error ±0.5mm) is used to prevent derailment. For example, the sliding resistance of its 2D armrest is controlled at 5-8N, which ensures smooth adjustment and avoids accidental sliding.

Angle rotation mechanism: using a friction damper + positioning pin combination, the damper torque needs to be set according to the adjustment dimension: the left-right swing damping of the 3D armrest is 1-2N・m, and the multi-angle rotation damping of the 4D armrest is 2-3N・m. The friction loss is reduced by silicone-based grease (viscosity ≥1000cSt), and the insertion depth of the positioning pin is ≥3mm to ensure that the deviation is ≤1° after the angle is locked.

Anti-loosening design: All connecting screws are coated with anti-loosening glue (such as Loctite 243), and the tightening torque is implemented according to ISO 898-1 standard (M4 screw torque 2.5-3.5N・m), and verified by vibration test (frequency 20-200Hz, acceleration 5g, lasting 2 hours) without loosening.

4. Manufacturing process control: precision management from mold to assembly

Injection molding process: hot runner mold (temperature control accuracy ±2℃), melt temperature 260-280℃, injection pressure 80-100MPa, holding pressure 40-60MPa, cooling time is set according to the thickness of the part (≥30 seconds), ensuring that the shrinkage rate of nylon parts is ≤0.8%, and the dimensional tolerance is controlled within ±0.1mm. The mold adopts German mirror polishing technology (roughness Ra≤0.2μm) to reduce the interference of injection burrs on the adjustment mechanism.

Metal parts processing: Adjustment shafts, gears and other metal parts are processed by CNC precision, with a dimensional tolerance of ±0.05mm, and the surface is treated with zinc-nickel alloy (plating thickness 5-8μm). The salt spray test is ≥500 hours without rust to avoid adjustment jamming caused by metal oxidation.

Assembly quality control: Establish a standardized assembly process (SOP), the assembly clearance of each adjustment joint is tested by a plug gauge (such as the radial clearance of the height adjustment shaft ≤0.1mm), and the tightening force of the key screws is calibrated with a torque wrench. After assembly, 100% functional testing is performed (adjust each dimension more than 3 times) to eliminate jamming, abnormal noise and other defective products.

5. Test verification: Multi-dimensional reliability evaluation system

Static load test: Apply 100N vertical force, 50N front and rear force, and 30N left and right force at the end of the handrail for 24 hours, measure the deformation ≤1mm, and restore the original position error after unloading ≤0.5mm. Products of Anji Xielong Furniture Co., Ltd. must pass the test of 3 times rated load (300N vertical force) without structural damage.

Dynamic fatigue test: Cycle test according to the adjustment frequency of different dimensions: 1D height adjustment 100,000 times, 2D forward and backward sliding 50,000 times, 3D angle adjustment 30,000 times. After the test, the looseness of the mechanism is ≤0.5mm, and the friction damping attenuation is ≤15%.

Environmental adaptability test: The armrest is placed in an environment of -20℃ to 60℃ for 24 hours each, and then functional test is performed. It is required that the resistance change under extreme temperature is ≤20%, and there is no plastic brittle cracking or deformation.

Ergonomic simulation test: Invite users of different body types (height 150-190cm, weight 50-100kg) to conduct a 30-day use test to collect feedback on the smoothness of adjustment and locking reliability. The satisfaction must reach more than 90 points (full score 100).

6. Usage maintenance and after-sales support: Extend the stability cycle

User training: The technical team provides customers with installation guidance and usage training, clarifies the adjustment range (such as the height adjustment range of 100-150mm) and the correct operation method (avoid violent adjustment), and reduces structural damage caused by improper use. For example, its training manual specifically states: The multi-angle adjustment of the 5D armrest needs to be operated in the order of "height first, then front and back, and finally angle".

Regular maintenance plan: It is recommended that users clean and lubricate the adjustment mechanism every 3 months, and use dry silicone-based lubricants (such as CRC 110) to spray on the sliding guide rails and rotating shafts to prevent dust accumulation and increase resistance. The company's after-sales service team can provide on-site maintenance services, with a response time of ≤24 hours.

Fault warning mechanism: The armrest has a built-in micro-motion sensor (optional configuration). When the adjustment resistance increases abnormally (exceeds 150% of the rated value) or the lock fails, an early warning is issued through the seat control system, and the user can contact the after-sales service in time to avoid the problem from expanding.

English

English  Español

Español  عربى

عربى