3D Armrests: The Fusion of Ergonomics and Future Design

What are 3D Armrests? Definition and Significance

What exactly is a 3D armrest? It’s an armrest designed and produced using advanced manufacturing techniques, particularly 3D printing. Unlike traditional armrests, which are often limited by mold and material shapes, 3D armrests can achieve highly complex geometric forms and curved surfaces. This allows for a much better fit with ergonomic principles. They’re more than just simple support structures; they’re a crucial element in modern design, enhancing user experience and product aesthetics.

3D printing technology is revolutionizing how armrests are designed and manufactured. This technology empowers designers to break free from conventional manufacturing constraints, creating armrests that are more personalized, integrate more functions, and boast more appealing aesthetics. From rapid prototyping to small-batch custom production, 3D printing offers unprecedented flexibility and efficiency.

302A 3D armchair arm rotating forward and backward

This article will delve into the unique design advantages of 3D armrests, their wide-ranging applications, and their future development. Our goal is to provide you with a comprehensive understanding of the immense potential of 3D armrests in blending ergonomics and future design.

3D Armrests: Design Advantages and Technical Realization

The prominence of 3D armrests across various sectors stems from their unparalleled design advantages and the advanced technology underpinning them.

Ergonomic Optimization: Tailored Comfort

One of the most significant benefits of 3D armrests is their capacity for ultimate ergonomic optimization. Through personalized customization, designers can precisely model armrests based on a user’s specific arm shape, size, and even preferred sitting posture, crafting a perfectly fitting support. This customization ensures the armrest distributes pressure evenly across the arm and elbow, significantly reducing fatigue during prolonged use. In terms of material selection, 3D printing also offers a broader palette, allowing for the use of lightweight, high-strength, durable, and comfortable-to-the-touch polymers or composite materials, further enhancing the user experience.

Design Freedom and Aesthetics: Breaking Traditional Boundaries

Compared to conventional manufacturing methods like injection molding, 3D printing technology grants designers unprecedented design freedom. This means armrests are no longer confined to simple straight lines and flat surfaces; they can effortlessly achieve incredibly complex and fluid geometric shapes and curves. These previously unimaginable structures not only improve the armrest’s ergonomic performance but also allow for unique aesthetic integration, transforming the armrest into a focal point of the product’s overall appearance and even reflecting a brand’s distinct DNA. Furthermore, 3D armrests can easily incorporate multifunctional integration, subtly concealing control panels, storage compartments, or even wireless charging ports within the armrest, perfectly blending practicality with beauty.

Manufacturing and Sustainability: Efficient and Eco-Friendly

The manufacturing process of 3D armrests also offers distinct advantages. 3D printing technology, as an additive manufacturing method, builds objects layer by layer. This translates to minimal material waste during production, significantly improving resource utilization. Simultaneously, it supports rapid prototyping, drastically shortening product development cycles and making design iterations far more efficient. On the sustainability front, as technology advances, an increasing number of eco-friendly and recyclable materials are being used in 3D printing, injecting a green essence into armrest production. For small-batch production or highly customized products, 3D printing’s production efficiency and cost-effectiveness significantly outperform traditional manufacturing methods.

3D Armrests: Application Scenarios

Thanks to their unique design advantages and manufacturing flexibility, 3D armrests are demonstrating immense potential across various industries, from everyday office use to high-end transportation.

Office Furniture: Enhancing Work Comfort and Efficiency

In the office furniture sector, 3D armrests are becoming an indispensable component of ergonomic office chairs. By precisely conforming to a user’s arms, they significantly boost comfort during long working hours, thereby indirectly improving productivity. For specialized workstations requiring high customization—such as chairs used by designers, gamers, or medical professionals—3D armrests can integrate more functions tailored to specific needs, providing specialized support and operational convenience.

Transportation: Balancing Luxury and Practicality

3D armrests are also playing an increasingly vital role in transportation interior design. In automotive interiors, particularly in luxury and concept cars, customized 3D armrests not only enhance driving and riding comfort but also showcase the vehicle’s unique design language and technological sophistication. In aerospace, the lightweight nature of 3D printing allows armrests to significantly reduce weight while maintaining strength, which is crucial for fuel efficiency and payload capacity. Similarly, in rail transport and marine vessels, 3D armrests can offer solutions that balance both comfort and functionality, adapting to the specific environments of different modes of transport.

Healthcare: Customized Rehabilitation and Care

In the healthcare sector, the application of 3D armrests focuses more on personalization and functionality. They are used in rehabilitation assistive devices, providing custom-tailored support for specific patients to aid in their recovery exercises. On medical beds and wheelchairs, 3D armrests can be adjusted according to the patient’s physical condition and needs, thereby significantly enhancing patient comfort and facilitating care for medical staff.

Home Living: The Fusion of Comfort and Intelligence

3D armrests are also gradually integrating into our home lives. In sofas and lounge chairs, they can provide more comfortable support, enhancing overall home comfort and design aesthetics. With the development of smart homes, future 3D armrests might even incorporate more intelligent functions, becoming part of smart home integration. This could include built-in sensors to monitor user posture or touch controls for smart devices, leading to a more convenient and personalized living experience.

3D Armrests: Challenges and Future Outlook

While 3D armrests offer numerous advantages in design and functionality, they still face certain challenges on the path to widespread adoption. However, with continuous technological advancements, their future development prospects remain bright.

Current Challenges

Firstly, material cost and printing speed remain a challenge for mass production. Although 3D printing is remarkably efficient for small-batch customization, achieving the economies of scale seen in traditional manufacturing requires further reductions in material costs and improvements in printing efficiency. Secondly, the cultivation of design software and talent is also crucial. Designing ergonomically sound and aesthetically innovative 3D armrests demands more specialized design tools and designers with interdisciplinary knowledge. Finally, surface finishing and durability are areas that require continuous improvement to ensure the final product meets consumer expectations for high quality and longevity.

3D Armrest vs 4D Armrest: Which is Better?

When choosing an office chair or gaming chair, consumers often encounter the question: which is better, a 3D adjustable armrest or a 4D armrest? In essence, a 3D armrest typically refers to one that can be adjusted in three directions, such as up/down, forward/backward, and pivot. A 4D armrest, however, adds a side-to-side adjustment to these, offering a more comprehensive range of customization options.

For office chairs, such as an office chair 3D armrest, a 3D armrest can already meet most users’ ergonomic needs, providing ample support and comfort. For gaming chairs, like a gaming chair 3D armrest, gamers often require more precise adjustments to accommodate various gaming postures. In this case, the extra dimension of adjustment offered by a 4D armrest becomes particularly important, better adapting to arm positions during mouse and keyboard operations.

Therefore, there’s no absolute “better” when it comes to 3D armrest vs 4D; the choice ultimately depends on the user’s specific needs and budget. For those seeking the ultimate adjustment experience and multifunctionality, a 4D armrest might be superior. However, for users prioritizing basic adjustment and value for money, a 3D armrest can still deliver excellent performance.

Future Development Trends

Looking ahead, the development of 3D armrests will become increasingly intelligent and personalized. We can foresee armrests integrating more intelligence and sensors, for example, real-time posture monitoring and health data feedback via sensors, or even automatic adjustment based on the user’s sitting posture. Breakthroughs in material science will also lead to the application of novel smart materials, such as those that are temperature or pressure adaptive. As manufacturing processes continue to mature and become more widespread, the production cost of 3D armrests will further decrease, driving their integration into more mass-market products.

Anji Xielong Furniture Co., Ltd., as a company specializing in the R&D, production, and sales of adjustable armrests for office chairs, fully understands the importance of these trends. Since its establishment in 2019, the company has consistently adhered to its purpose of “Quality first, customers first,” continuously innovating and expanding in pursuit of higher quality products. We believe that through sincere cooperation with peers in the furniture field, exploring the infinite possibilities of 3D armrests and 4D armrests, we will provide customers with high-quality products and efficient services, jointly creating a win-win future.

Feel free to contact us

Feel free to contact us

- Product Fast Links

- Office Chair Armrest

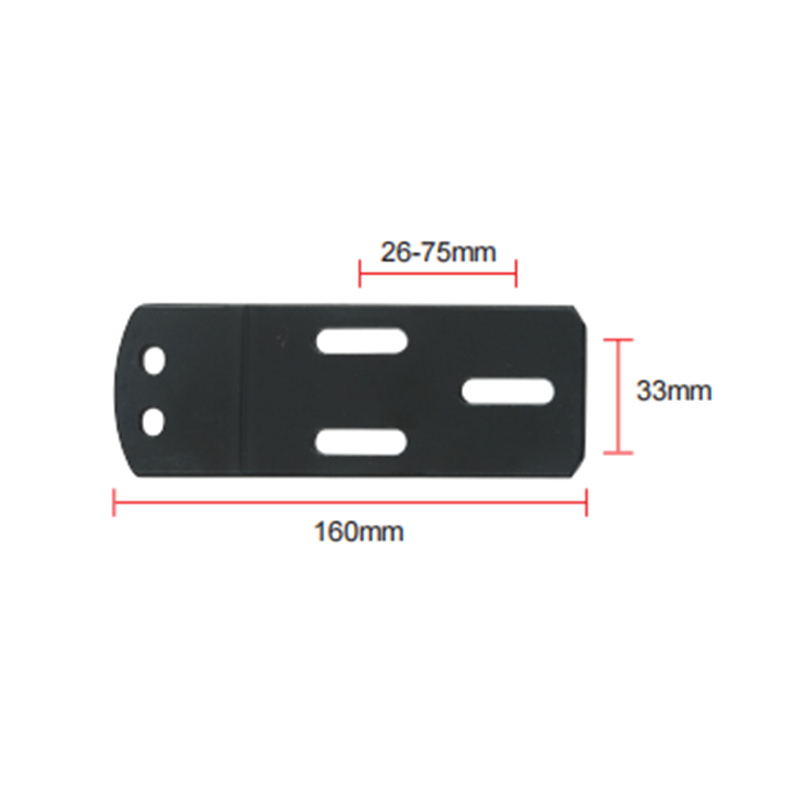

- Hardware Steel Plate

- Polyurethane PU Surface

- Casters

- Chair Frameworks & Structures

- Contact Information

- Tangpu Industrial Park, Anji County, Huzhou City, Zhejiang Province, China

- [email protected]

- +86-13567973388

English

English  Español

Español  عربى

عربى