The Ultimate Guide to Universal Casters: Selection, Uses, and Benefits

- 1 What Are Universal Casters and Why Are They So Widely Used?

- 2 How to Choose the Best Casters for Heavy Duty Applications

- 3 Office Chair Caster Replacement: A Step-by-Step Guide

- 4

- 5 Polyurethane vs. Rubber Wheels: Which is Right for You?

- 6 Understanding Caster Wheel Sizes and Their Impact on Performance

- 7 FAQ

Universal casters are the unsung heroes of mobility, providing effortless movement to a vast array of equipment across industries. From office chairs to heavy-duty industrial carts, the right caster can dramatically improve efficiency and safety. This comprehensive guide delves deep into the world of universal casters, exploring their types, applications, and how to select the perfect one for your specific needs. We will demystify key considerations like load capacity, wheel material, and swivel mechanisms, empowering you to make an informed decision.

What Are Universal Casters and Why Are They So Widely Used?

Universal casters are wheel assemblies designed to be attached to a wide variety of objects, typically featuring a standardized top plate or stem for easy installation. Their "universal" nature stems from their adaptability; they are not custom-made for one specific piece of equipment but are engineered to fit a broad range of applications. This versatility makes them a go-to solution for adding mobility quickly and cost-effectively.

- Standardized Mounting: Most feature a common top plate pattern (e.g., 4-hole 3" x 3" square or 2.5" x 2.5") or a common stem size (e.g., 7/16" diameter).

- Interchangeability: They can often replace worn-out casters on existing equipment without modification.

- Economic Efficiency: Mass production for a wide market keeps costs lower than highly specialized casters.

- Immediate Availability: They are widely stocked and available from numerous suppliers, reducing downtime.

How to Choose the Best Casters for Heavy Duty Applications

Selecting casters for heavy duty applications is critical for both safety and performance. A failure under load can lead to product damage, workplace accidents, and costly injuries. The key is to not only look at the load rating per caster but to understand the factors that contribute to that rating and ensure it matches your operational environment.

- Load Capacity Calculation: Always calculate the total load the equipment will carry, then divide by the number of casters. For safety, choose casters with a rating that exceeds this number by at least 20-25% to account for dynamic forces, impact, and uneven floors.

- Wheel Material: Hard wheels like polyurethane or forged steel offer excellent load-bearing properties and are resistant to abrasion, but can transmit vibration and may not be suitable for delicate floors.

- Bearing Type: For heavy loads, precision roller bearings or tapered bearings are superior to simple raceways, as they distribute weight more effectively and roll with less effort.

- Frame Construction: Look for a forged or pressed steel frame, often with a double-ball race swivel mechanism for smooth rotation under extreme weight.

| Factor | Consideration for Heavy Duty Use |

| Load Rating | Choose a rating 25-30% higher than the static weight. |

| Wheel Diameter | Larger wheels (6"+) overcome obstacles more easily and reduce rolling resistance. |

| Wheel Hardness | Softer wheels (e.g., rubber) protect floors but can flatten under load; harder wheels (e.g., poly) maintain shape. |

| Swivel Lock | Essential for stability during loading/unloading and for straight-line movement. |

Office Chair Caster Replacement: A Step-by-Step Guide

Worn-out casters are a common issue, leading to difficulty in movement, damaged flooring, and an unstable seating experience. An office chair caster replacement is a simple and inexpensive DIY task that can extend the life of your chair and protect your floors. The process is generally straightforward, but knowing the type of mount your chair uses is the first step.

- Identify the Mount Type: The two most common types are stem mounts (a metal or plastic peg) and top plate mounts (a flat plate with holes for screws).

- Stem Removal: For stem casters, firmly grip the caster and pull straight up. If it's stuck, gently tapping with a hammer or using a pair of pliers for leverage can help.

- Top Plate Removal: For plate-mounted casters, simply unbolt them from the base of the chair using a screwdriver or wrench.

- Installation: Insert the new stem into the socket or align the new plate with the holes and secure it with the provided bolts. Ensure it is snug and does not wobble.

60/32 Five-Hole Green Racing Wheel Mesh Chair Caster Accessories

Polyurethane vs. Rubber Wheels: Which is Right for You?

The debate between polyurethane vs. rubber wheels is central to selecting the right caster. Each material offers a distinct set of properties that make it suitable for specific environments and tasks. Understanding these differences is key to optimizing performance, protecting floors, and ensuring operator comfort.

- Polyurethane Wheels: Known for their exceptional durability and resistance to oils, chemicals, and abrasion. They have a high load capacity and leave no marks, making them ideal for industrial and warehouse settings. However, they can be noisy and may transmit vibration.

- Rubber Wheels: Softer than polyurethane, they provide superior traction, a quieter ride, and excellent shock absorption. They are perfect for offices, hospitals, and homes where floor protection and noise reduction are priorities. The downside is that they can mark certain floors over time and may wear faster under heavy loads.

| Characteristic | Polyurethane Wheels | Rubber Wheels |

| Floor Protection | Excellent (non-marking) | Very Good (may mark some floors) |

| Noise Level | Moderate to High | Low |

| Load Capacity | Very High | High |

| Rolling Resistance | Low (rolls easily) | Higher (requires more effort) |

| Ideal For | Factories, Warehouses, Workshops | Offices, Hospitals, Libraries, Homes |

Understanding Caster Wheel Sizes and Their Impact on Performance

The diameter and width of a caster wheel are not arbitrary measurements; they are fundamental engineering choices that directly influence the caster's performance. Choosing the correct caster wheel sizes is crucial for ensuring easy maneuverability, overcoming obstacles, and maintaining stability.

- Wheel Diameter: This is the most critical size factor. Larger wheels require less force to start and maintain rolling because they reduce the friction coefficient. They can also roll over cracks, cords, and debris much more easily than smaller wheels.

- Wheel Width: A wider wheel provides a larger contact area with the floor, which increases stability and distributes the load over a broader surface, protecting delicate floors. Narrow wheels are useful in applications with limited space or where precise maneuverability is needed.

- Overall Height: The total height of the caster (wheel + fork) determines how high the equipment will be lifted off the ground. This is important for ensuring the equipment remains stable and functional.

FAQ

What is the weight capacity for a typical universal caster?

There is no single "typical" capacity, as universal casters are designed for a wide range of uses. Capacities can range from as low as 60 lbs per caster for light-duty office chairs to over 1,500 lbs per caster for heavy-duty industrial models. The key is to always check the manufacturer's rated capacity. To find the right one, calculate the total weight your equipment will carry (including its own weight), divide by the number of casters, and then select a caster with a capacity that is 25-30% higher than that number to account for dynamic forces and safety.

Can I replace my office chair's carpet casters with ones for hard floors?

Absolutely, and it is highly recommended. Office chair casters designed for carpet are typically rigid and have sharp edges that can dig into and scratch hard surface floors like hardwood, laminate, or tile. Replacing them with soft-wheeled casters, often called "universal hard floor casters," is a simple process. These feature wheels made of soft rubber or polyurethane that are non-marking and will glide smoothly while providing excellent protection for your flooring investment.

How do I stop my swivel casters from wobbling?

A wobbling caster is often a sign of wear or improper installation. First, check that the caster is fully and securely seated in its mount (stem or plate). If it is secure but still wobbles, the issue is likely wear in the swivel mechanism or the wheel axle. For stem casters, the socket in the chair leg itself may be worn. The most reliable solution is to replace the worn caster(s). Continuing to use a wobbly caster can lead to further damage to the equipment and creates a safety hazard due to instability.

What is the difference between a caster and a wheel?

This is a fundamental distinction. A wheel is a single round component that rotates on an axle. A caster is a complete assembly that includes a wheel (or wheels) mounted within a fork (or horn), and that fork is attached to a swivel mechanism (a kingpin and raceway) allowing it to rotate 360 degrees. Therefore, all casters have wheels, but not all wheels are part of casters. A fixed, non-swiveling wheel assembly is typically just called a "wheel" or "rigid wheel," not a caster.

Feel free to contact us

Feel free to contact us

- Product Fast Links

- Office Chair Armrest

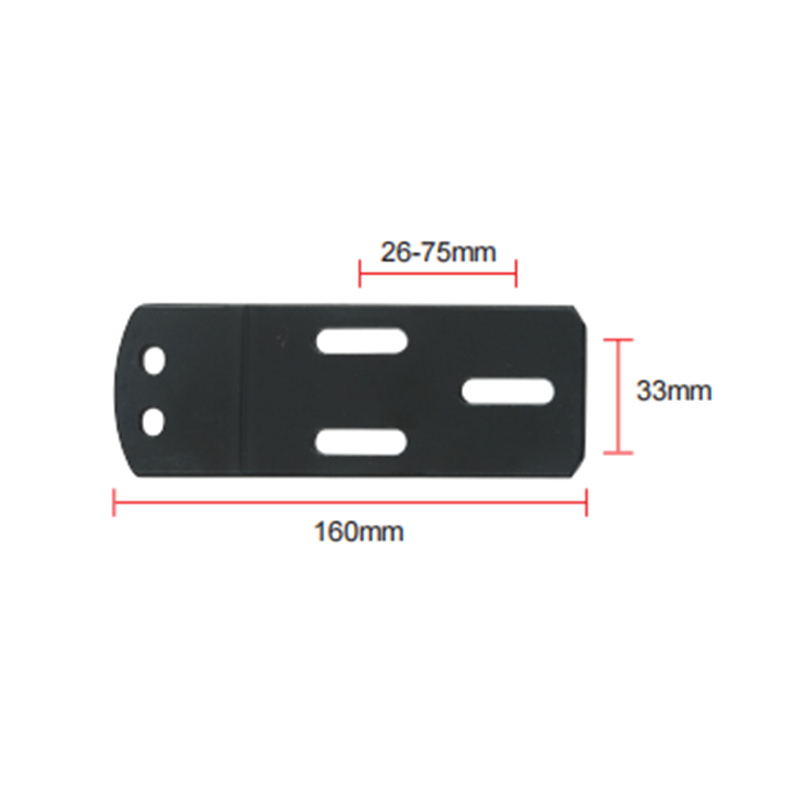

- Hardware Steel Plate

- Polyurethane PU Surface

- Casters

- Chair Frameworks & Structures

- Contact Information

- Tangpu Industrial Park, Anji County, Huzhou City, Zhejiang Province, China

- [email protected]

- +86-13567973388

English

English  Español

Español  عربى

عربى